Garment Lab Equipment List in Bangladesh

What is Fabric Testing?

Testing is one of the most fundamental pieces of any item improvement and keeps up with item quality. The outcomes show how well the item will remain against the impact of time, how might the item contrast from when it was created, can the item satisfies its motivation.

Testing: Testing implies checking, looking at, and confirmation of certain things. On the alternate way, we can characterize testing as; it is the interaction or system to decide the nature of an item.

The object of testing:

- Research

- Choice of a natural substance

- Process control

- Process advancement

- Item testing

- Particular test

Testing is administered by 5M, which are: Man, Machine, Material, Technique, and Estimation.

Quality: The term quality alludes to the greatness of an item. At the point when we say the nature of an item is great. We imply that the item is really great for the reason for which it has been made.

Control: To check or confirm and subsequently to direct.

Quality Control: Quality control is the engineered and normal control of the variable which influences the nature of an item. It is the checking, confirmation, and guideline of the level of greatness of a trait or property of something.

The functional strategies and exercises that support the nature of an item or administration to fulfill given prerequisites. It comprises value arranging, information assortment, information investigation, and execution and is material to all periods of the item life cycle; plan, assembling, conveyance and establishment, activity, and support.

Objects of Value Control: To create required quality items.

- To satisfy the client's interest.

- To diminish the creation cost.

- To decrease wastage.

- To procure the most extreme benefit at the least expense.

Quality Control in Apparel Manufacturing

Quality is a relative term. It implies client needs is to be fulfilled. Quality is of prime significance in any part of the business. Clients request and anticipate an incentive for cash. As makers of clothing, there should be a consistent undertaking to deliver work of good quality.

The different Strides of Pieces of clothing fabricating where in-process review and quality control are done are referenced underneath

- In Example making segment

- In-Marker making segment

- Assessment in texture spreading segment

- Assessment in texture cutting segment

- Assessment in texture sewn segment

- Assessment in squeezing and Completing segment

Quality Control in Sample Area:

- Keeping up with purchaser's Particular norm

- Really looking at the example and its various issues

- Estimations checking

- Texture tone, gsm, Quickness, and so forth properties required checking

- Spi and other boundary checking

Quality Control in Marker Making:

- To check indent or drill mark

- The texture width should be higher than the marker width

- Texture length should be higher than marker length

- Matching of the green line

- Check design size and aspect

- Matching of register and stripe taking with thought

- Taking into account pieces of the clothing creation plan

- Cutting table length thought

- Design bearing thought

Quality Control in Cloth Spreading:

- Texture spreading as per the right arrangement with marker length and width

- Keep up with the necessities of spreading

- Matching of check and stripe

- Lay contains the right number of texture employ

- Right Utilize course

- To control the texture joining

- Strain control

Quality Control in Cloth Cutting:

- The component of the example and the cut piece ought to be the same and precise

- The cut edge ought to be smooth and clean

- The score ought to be cut finely

- Drill opening ought to be made at the appropriate spot

- No yarn fraying ought to happen at the cut edge

- Keep away from edge redirection

- Keep up with the cutting point

- More gifted administrators utilizing

Quality Control in Sewing Area:

- Input material checking

- Cut board and adornments checking

- The machine is in good condition

- String count check

- Extraordinary work like weaving, printing board check

- Needle size checking

- Sewing shortcomings ought to be checked

- Pieces of clothing estimation check

- Crease shortcoming check

- Size botch check

- Confusing matching of managing

- Conceal variety inside the fabric

- The wrong situation of interlining

- Wrinkled or wrinkle appearance control

Quality Control in Finishing Area:

- Appropriate examination of the articles of clothing including estimation, spot, soil, contaminations

- Water spot

- Concealing variety check

- Smooth and unfurl in pocket

- In got or broken chain or button

- Wrong overlap

- Legitimate shape in articles of clothing

- Appropriately dried in subsequent to squeezing

- Needed kink or crease in coating

- Get up checking

- Collar shutting

- Side crease

- Sleeve placket append

- Sleeve append

- Base trim

- Back burden

- Each piece of a body

Quality Control of Sewing String and Zipper

Quality Control of Sewing String:

A thin, solid strand or line, particularly one intended for sewing or other embroidery. Most strings are made by handling and bending yarns. A wide assortment of string types are being used today, e.g., turned cotton and turned polyester, center-turned cotton with a polyester fiber center, polyester or nylon fibers (frequently fortified), and mono-fiber strings.

Sewing string

The following Elements of Sewing String are thought of:

- String Development/Ticket number

- String count

- String Handle

- Number of contorting

- String balance

- String Relentlessness

- String Prolongation

- Sew capacity

- Blemish

- String finish

- String tone

- Bundle Thickness

- Winding

- Yardage

Quality Control in Zipper:

A zipper, zip, or zip clasp, is a usually involved gadget for briefly joining two edges of texture. It is utilized in clothing (e.g., coats and pants), baggage and different packs, outdoor supplies, setting up camp stuff (for example tents and camping cots), and different things.

Zipper

The following Variables are viewed in Zipper:

- The appropriate component of the zipper

- The top and base ends ought to be accurately sewn

- The tape and shade of the zipper ought to be uniform

- The slider must be locked appropriately

- The slider ought to move appropriately

Textile Quality Control Framework:

- On-line quality control framework

- Of-line quality control framework

On-Line Quality Control Framework:

This sort of value control is done ceaselessly by the creation interaction. During the running of the creation process an arrangement is naturally performs and distinguish the shortcoming and furthermore takes remedial action. Online quality control includes unrefined substance quality control and interaction control.

Natural substance Control:

As quality item relies upon natural substance quality so we should be furnished with the best quality natural substance with practical thought. The texture should be without issue, with legitimate sponginess, and whiteness according to the prerequisite of the resulting system. The Dim investigation report gives the state of the crude texture.

Process Control:

The strategy picked for the interaction should be given important precise boundaries. Here the particular gravity, water level, remaining hydrogen peroxide, and so on at each stage is checked.

Textile Research Center:

The lab is at the top of the textile ventures. A higher accuracy lab can help effectively to accomplish the objective of the association. Before mass creation, an example of the endorsement from industry is shipped off the purchaser. According to the necessity of the purchaser, the shade is ready in a lab thinking about the monetary perspectives.

Lab-Line:

Standard example: The purchaser to the business gives the standard example. The example is estimated by the CCM to get the recipe.

2.Lab preliminary: Getting the recipe the lab official produces lab preliminary and coordinates with standard as per purchaser necessity. Lab preliminary is made by the AHIBA coloring machine. There are a few projects for coloring. The projects are given beneath.

Offline Quality Control Framework:

Acted in the lab and another creation region by halting the creation cycle comprising of texture assessment and research center and another test. Rectification steps are taken by the experimental outcome.

Offline Tests: Every one of the Disconnected tests for completed textures can be gathered as follows:

- Actual tests

- Compound tests

Actual Tests:

- GSM test

- Shrinkage test

- Spiraled test

- Elasticity

- Scraped spot obstruction

- Pilling opposition

- Button Strength Testing

- Wrinkle opposition

- Layered security

- Blasting strength test

Compound Tests:

- Color Fastness to washing.

- Color Fastness to Light.

- Color Fastness to Warm.

- Color Fastness to Chlorinated Water.

- Color Fastness to water spotting.

- Color Fastness to Sweat.

- Color Fastness to Seawater.

- Fiber examination.

- PH test.

- Repellency

Significance of Textile Testing | Explanations behind Testing of Textile

The testing of textile items is a costly business. A research center must be set up and outfitted with a scope of test hardware. Prepared agents must be utilized whose compensations must be paid consistently, not when results are required. Besides this large number of expenses are useless and accordingly add to the last expense of the item. In this way, it is vital that testing isn't embraced without adding an advantage to the eventual outcome. There are various focuses in the creation cycle where testing might be completed to work on the item or to forestall unsatisfactory products advancing further in the cycle.

Fig: Different testing of textile

Significance of Textile Quality Control Testing:

The essential goal of textile testing is to survey the item's properties and anticipate its exhibition during use. The data acquired might be utilized for the accompanying:

- Innovative work

- Determination of unrefined components/inputs

- Process improvement

- Process control

- Quality control

- Item testing

- Item disappointment investigation

- Near testing and seat stamping

- Congruity with unofficial laws and particulars

- Purposes Behind Textile Testing

- Actually taking a look at Unrefined components

- Checking Creation

- Surveying the End result

- Examination of Flawed Material

- Item Advancement and Exploration

- Really looking at Unrefined components

The creation cycle, taking everything into account begins with the conveyance of natural substances. On the off chance that the material is mistaken or unsatisfactory, delivering the expected nature of the end result is unimaginable. The textile business comprises various separate cycles, for example, normal fiber creation, man-made fiber expulsion, fleece scouring, yarn turning, winding around, coloring and completing the process of, weaving, article of clothing assembling, and creation of family and specialized items. These cycles are frequently completed in discrete foundations, subsequently what is viewed as a natural substance relies upon the stage in handling at which the testing happens. It very well may be either the crude fiber for a spinner, the yarn for a weaver, or the completed texture for a piece of clothing producer. The approaching material is checked for the necessary properties with the goal that unsatisfactory material can be dismissed or suitable changes made to the creation conditions. The guidelines that the natural substance needs to meet should be set at a practical level. On the off chance that the guidelines are set too high, the material will be dismissed that is adequate for the end user, and in the event that they are set too low, a lot of mediocre material will proceed into creation.

Observing Creation

Creation observing, which includes testing tests taken from the creation line, is known as quality control. Its point is to keep up with, inside known resiliences, certain predefined properties of the item at the level at which they have been set. A quality item for these objects is characterized as one whose properties meet or surpass the set particulars. Other than the need to do the tests accurately, fruitful checking of creation likewise requires the cautious plan of suitable examining methodology and the utilization of measurable examination to figure out the outcomes.

Evaluating the Eventual outcome

In this cycle, the mass creation is analyzed before conveyance to the client to check whether it meets the determinations. Its tendency, this happens after the material has been delivered. It is accordingly past the time to change the creation conditions. At times chosen tests are tried and in different cases, all the material is checked and steps are required to amend shortcomings. For example, a few characteristics of texture are examined for broken places which are then retouched by gifted agents; this is a typical piece of the cycle and the material would be dispatched as first quality.

Examination of Defective Material

In the event that broken material is found either at conclusive review or through a client grumbling it is vital that the reason is disconnected. This empowers moves toward being taken to wipe out defective creations in the future thus giving a superior quality item. Examinations of shortcomings can likewise include the assurance of which party is answerable for defective material on account of a question between a provider and a client, particularly where cycles, for example, completing have been embraced by outside organizations. Work of this nature is frequently contracted out to free research facilities which are then ready to offer a fair-minded viewpoint.

Item Improvement and Exploration

In the textile business innovation is changing constantly, bringing adjusted materials or various strategies for creation. Before any changed item arrives at the commercial center it is important to test the material to make sure that the properties have been improved or have not been corrupted by quicker creation strategies. In this manner, a superior item or a cheaper item with similar properties can be accommodated by the client. A huge association will frequently have a different division to complete innovative work; in any case, it is important for the ordinary obligations of the testing division.

Color Quickness Test to Light | Light Speed Grades

The reason for the Color speed-to-light test is to decide how much the color will blur when presented to a known light source. It is a disconnected quality affirmation framework. For the most part, man wears the texture and goes beyond the home for taking care of their business. In the day; daylight fall on the textured surface. So it has to know how much insurance capacity has a texture to daylight. Not entirely settled by a trial called color speed to light. To gauge the color quickness a blue scale is utilized. In the wake of finishing the test, the test is contrasted and the blue scale.

Guideline of Color Fastness to Light:

This test estimates the protection from blurring of colored textiles when presented to sunlight. The test is presented to light for a specific time frame which is around 24 hours to 72 hours or by client/purchaser interest and contrasts the change and unique unexposed test the progressions are evaluated by Blue Scales.

Color Speed to Light with the Micro sol Light Quickness Analyzer:

- The testing is done bit by bit. The following step is kept up with during measuring the color belatedness to light. Cut the four bits of test examples as per the length and width wise and appended with the example holder.

- Then, at that point, the holder is set into the Microsol light quickness analyzer.

- Then the investigation went on for 72 hours as indicated by the purchaser's necessity.

- Following 72 hours after the fact the example was taken from the light quickness analyzer.

- Then, at that point, the test example contrast and the Blue scale or PC color matching framework (CCMS)

Presentation of Squeezing Quickness Test | Color Speed to Squeezing

Color Quickness to Squeezing:

Squeezing quickness trial of colored and printed textile items is performed to decide of obstruction of textiles to pressing and handling on chambers. Various tests are performed by when the textile is dry, when it is wet, and when it is soggy.

Reason and Extension:

This strategy is utilized for deciding the obstruction of the color of textiles of various types and in all structures to pressing and handling on hot chambers. Tests are given for hot squeezing when the textiles are wet when it is moist, and when it is dry.

Mechanical assembly and Reagent

Hand iron of legitimate load to give a tension of roughly 30g/sq.cm at the temperature showed in the accompanying;

- Cotton and Material 190-200C˚

- Fleece, Silk, and Gooey 140-160C˚

- Cellulose acetic acid derivation and Polyamide 115-120C˚

- White blanched cotton material weighing roughly 125g/sq.meter. Five pieces at the very least 14×4 cm are required.

- Dark scale by surveying change in color and staining. (ISO scale)

- The size of the example is 10×4cm

Working Procedure

Example planning

Example of materials, which has been exposed to any intensity or drying therapy, should be permitted to condition at 65% RH, temp. 20±2C˚, before they tried.

Dry Squeezing

Put the example on the piece of dry cotton material on a smooth even surface. Put the iron on the example and leave it for 15 Sec.

Damp Squeezing:

The adjoining texture in components of 100 mm x 40 mm is submerged into the water and, crushed as 100 percent get. A dry example is put onto the undyed cotton texture on the filler and, the wet contiguous texture is put onto them. The top layer of the gadget is pulled down and, the dry example is squeezed for 15 seconds at the decided temperature. The adjustment of color of the example is assessed in two unique ways as per the dim scale.

a) Not long after the finish of the test

b) Subsequent to molding for 4 hours under standard climatic conditions.

The smudging to undyed textures is assessed by dark scale.

Wet Squeezing

Absorb the example and cotton fabric refined water and crush or concentrate them to contain their own load of water. Put the wet example on a piece of the dry cotton fabric and put the wet cotton material on the example, press by moving the iron forward and backward over the wet material (without extra strain) for 15 sec.

Evaluation

Evaluate the adjustment of color of the example with proper dim scale.

Standard

Dry Squeezing 4

Wet Squeezing 3-4

Introduction to Perspiration Test

The color speed to sweat (corrosive and basic) will be essentially level 3-4 (color change and staining). This measure doesn't have any significant bearing on white items, to items that are neither colored nor printed, to furniture textures, shades, or comparable textiles planned for inside embellishment. A degree of 3 is in any case permitted when textures are both light colored (standard profundity < 1/12) and made of silk or of mixes with over 20% silk. This sort of test is exceptionally applied for active apparel and weighty dresses which is utilized uniquely. Ordinary materials are additionally tried by sweat test.

Color Fastness to Perspiration

The articles of clothing which come into contact with the body where sweat is weighty may experience serious neighborhood discoloration. This test is planned to decide the obstruction of color of colored textiles to the activity of acidic and antacid sweat. Prior to being familiar with the Color Speed to Sweat you should need to be aware of Color Quickness to Wash and Color Speed to Scouring.

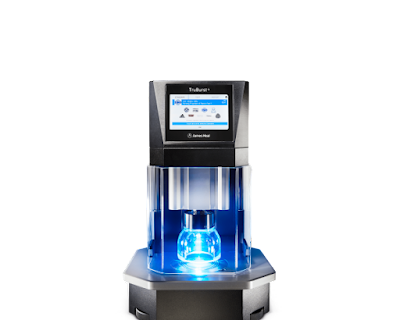

Fig: per spirometer

Perspiration matters which impacts Color Fastness.

Reason and Degree

This technique is utilized to decide the opposition of the color of textiles of numerous types and in all structures to sweat.

Hardware for Speed Estimation

Perspiration analyzer

- Broiler, Kept up with at 37+-2 Degree centigrade

- Multi-fiber test texture

- Greyscale

- Color-matching cabinet Lightbox

- Acidic and Soluble arrangement

- Glass or Acrylic plat

Arrangement newly ready, containing 0.5g 1-histidine mono-hydrochloride mono-hydrate, 5g sodium chloride, and 2.5g disodium hydrogen orthophosphate per liter carried to PH 8.0 with 0.1N sodium hydroxide.

Arrangement newly ready, containing 0.5g 1-histidine mono-hydrochloride mono-hydrate, 5g sodium chloride, and 2.2g sodium dihydrogen orthophosphate per liter carried to PH 5.5 with 0.1N sodium hydroxide.

Two undyed materials for every example each 6×6cm of a similar sort of fiber as the example. Place the example between the two bits of white fabric and sew along one side to frame a composite example.

Working Strategy:

Completely wet one composite example in an answer of PH8.0 at the alcohol proportion of 20:1 and permit it to stay in this arrangement at room temperature for 30min. pour off the arrangement and spot the composite example between two glasses plates estimating around 7.5×6.5cm under a power of around 4.5kg.

Treat the other example similarly however with the arrangement at PH 5.5.

Place the contraption containing the examples in the broiler for 4 hours at 37±2C˚

Separate the example from the white material and dry them separated in air at a temperature not surpassing 60C˚

Evaluate the adjustment of color of the example and the smudging of the white material with the greige scale.

Quickness is a spot, for example, a palace, which is viewed as protected on the grounds that it is hard to reach or simple to guard against assault. This test is intended to decide the level of color which might be moved from the outer layer of a colored texture to indicate test fabric for scouring (which could be dry and Wet).

There are two test techniques for rubbing fastness.

- ISO-105-X12

- AATCC-08

In ISO-105-X12 the wet pickup of the scouring material is 100 percent . While in AATCC-08 the wet Pickup of the scouring fabric is 65%.We really look at scouring by Dry and Wet techniques. In wet scouring, we wet the scouring fabric as per the test technique and give a rating by contrasting the Smudging and the dark scale.

Comparatively, for dry scouring, we really look at the scouring with dry scouring material and contrast the smudging And dark scale for evaluations. Color Quickness to scouring is a fundamental test that is constantly expected for each colored texture it is possible that it is Printed or colored.

On the off chance that the color's quickness to scouring is great, its different properties like washing speed and strength and so forth improve consequently in light of the fact that the scouring is a strategy to really take a look at the obsession of the color on the texture. So assuming the obsession is great its washing properties will be great.

Rubbing Fastness s relies upon:

- Nature of the Color

- The profundity of the Shade

- Development of the Texture Idea of the color Each color it is possibly that it is shade, Responsive, distributed, or guided has its own quickness properties to scouring. There are a few colors like dark, Red, Burgundy, and Naval force blue which have unfortunate Color quickness properties due to their synthetic design.

- Like Dark color is a carbon base color and the molecule size of carbon is enormous than different colors which is the reason its scouring properties are poor. Comparatively red and blue are in a similar case. So to further develop the color speed we add more fastener to further develop the quickness properties of these colors. It doesn't imply that we can not accomplish the best outcomes with these colors. The necessary outcomes can accomplish however creation cost will be increment. Then again the development of the texture additionally impacts the speed properties.

Rubbing Fastness Test

In the event that the scouring speed on 100.80/40.40 is 3 on the dark scale, it will be 2-3 on 52.52/22.22 with similar printing boundaries. So consistently remember these impacts during finishing the expected boundaries with your client.

Continuously Check

- Quality development

- Color

- The profundity of the Color

- End Utilization of the item

Results that we can accomplish in Typical Circumstances are:

Dark Shade

Medium shades

Light Shades

Dry wet

Dry : 3-4 4 4-5

Wet: 2-2.5 3 3.5-4

Color Fastness Test | Washing Fastness Test| Fastness Test | Color Fastness Test to Washing

Color Fastness Test:

The property of a color holds its color when the colored (or printed) textile material is presented to conditions or specialists like light, sweat, air gases, or washing that can eliminate or obliterate the color. A color might be sensibly quick to one specialist and simply reasonably quick to another. The level of speed of color is tried by standard methodology. Textile materials frequently should meet specific quickness details for a specific use.

Washing Fastness Test Test

It is consistently helpful and fascinating to test the color which is to be utilized on an example of the yarn or texture to be colored. The result will rely upon the texture, the severe that has been utilized and the color that has been picked. Testing is best done on a progression of Groundnuts set apart (for recognizable proof) examples, which have been severe with various different mordants. Tests can be done for light, water, and washing speed utilizing straightforward standard test techniques.

To Test for Washing Fastness Test Follow these Means:

Take two bits of texture around 5cm by 5cm, one of which is undyed cotton and the other undyed fleece. Line them together along one side.

Take some example segments of the colored yarn and spread them uniformly between the two bits of material with the goal that they cross over the two sides. In the event that colored fiber is being tried a brushed example can be utilized instead of the yarn.

Sew around each of the four sides of the fabric with the goal that the yarn is held set up.

Set up a comparative example with colored materials that have good properties and spot them in two containers with screw covers containing an answer of 5gm per liter cleanser or cleanser arrangement at 30oC.

Unsettle the two containers tenderly for 30mins, then eliminate the textures and wash them delicately in clean water for 5mins. Open the sewing and separate the parts of dry in air. Assessment:

Place the colored yarn close to an example of a similar material that has not been tried, and look at the change which has occurred. Contrast additionally and the control test with palatable properties. In the event that the coloring being tried shows equivalent or less change than the palatable example, then it is comparable to the acceptable example.

Place the fleece and cotton fabrics close to tests of a similar material that have not been tried and contrast them and the materials that have been tried with a palatable coloring. Equivalent or less staining shows equivalent or better speed.

Washing Fastness Test | Wash Fastness | Depiction of Washing Fastness Te | Sorts of Washing Fastness

Color Fastness Test:

Colorfastness is the capacity of textures to hold the colors used to color them. A few textures hold color inside their filaments incredibly well - like denim - while others don't (for the most part manufactured or fake non-regular textures) and tend to "drain" when they are washed. The denim would subsequently be more "color quick" than the other texture.

The opposition of a material to change in any of its color qualities, when exposed to washing is called color quickness to washing.

Fastness Test

An example of the textile to be tried, with the nearby texture connected is exposed to washing under indicated conditions. to the degree of any adjustment of color and that of the smudging of the nearby texture are evaluated and the rating is communicated in quickness numbers.

There are two sorts of nearby textures; (1) single fiber texture and different fiber texture. On account of the multi-fiber texture only one example is required and in the single-fiber texture two nearby textures are required.

There are different colorfastness tests. Subtleties of washing quickness tests are given underneath.

Fastness Test to Washing:

In the test, changes in the color of the textile and furthermore smudging of color on the contiguous texture are surveyed. A 10 x 4 cm pattern of the colored texture is taken and is sandwiched between two contiguous textures and sewed, The example and the nearby texture are washed together. Five distinct kinds of washing are indicated as various washing strategies.

Washing fastness testing by Gyro wash

The answer for washing ought to be ready to the necessary temperature of washing. The alcohol material proportion is 50:1. In the wake of soaping treatment, eliminate the example, flush two times in chilly water and afterward in running virus water under a tap. Press it and air dry at a temperature not surpassing 60°C. The adjustment of color and staining is assessed with the assistance of dim scales.

The answer for washing ought to be ready to the necessary temperature of washing. The alcohol material proportion is 50:1. In the wake of soaping treatment, eliminate the example, flush two times in chilly water and afterward in running virus water under a tap. Press it and air dry at a temperature not surpassing 60°C. The adjustment of color and staining is assessed with the assistance of dim scales.

What is Textile Fabrics Testing?

01

Textile testing is really taking a look at the quality and reasonableness of natural substances and choice of material.

02

Fabric Testing is a significant part of textile creation, dispersion, and utilization.

03

There are a few purposes behind textile testing, for example, really taking a look at unrefined components, observing creation, surveying the Eventual outcome, examination of flawed material, item improvement, and exploration.

Basic Testing Equipment Used in the Fabric Testing Laboratory

- Moisture Meter

- Crock meter

- Digital box pilling tester

- Gsm cutter

- Gsm Balance

- Thickness gauge

- Shrinkage Template

- Color Assessment Cabinet Lightbox

- Lux Meter

- Pantone Color Guide

- Tumble Dryer

- Washer

- Button Pull Tester

- Needle Detector Machine

- Grey Scale

- Dehumidifier

- Yarn Twist Tester

- Magnifying Pick Counter

- Color Fastness Tester

- Hot Air Oven

- Crocking Cloth

- Temperature Meter

- Color Vision Hue Tester

- Orbital Mechanical Shaker

- Bond Test Machine

- Digital Calipers

- What is Fabric Bursting Strength Tester and How its Work?

The distending force, which is applied at the right points to the plane of the fabric, under determined conditions, will bring about the burst of material.

Fabric bursting strength test is an elective strategy for estimating strength in which the material is focused on all paths simultaneously and is in this manner more appropriate for such material

Model: Parachute fabrics, Channels, Sacks, Nets, paper, and furthermore knitted fabrics.

Knitted fabric: A construction created by interloping at least one closure of yarn or similar material.

Woven fabric: A construction created when no less than two arrangements of strands are entwined, for the most part at right points to one another as per a foreordained example of intertwining, and to such an extent that something like one set is lined up with the pivot along the long way course of the fabric.

Sorts of Fabric Bursting Strength Test:

Bursting strength:

At the point when the fabric is exposed to pressure, the fabric starts to extend in every one of the potential headings simultaneously. At the point when the applied strain increments continuously, the fabric starts to burst in the wake of crossing a tension cutoff. This strain limit is called bursting strength. Subsequently, we can say that "the strain expected to burst the fabric surface is named as bursting strength of the fabric". It is estimated in pounds (lbs.) per inch2 or kilograms per Centimeter2. The bursting strength of the fabric is a vital property for parachute fabric. Kind of yarn and material utilized in the fabric, the count and development of the fabric enormously influence the bursting strength of the fabric.

Device needed:

1 - Diaphragm bursting strength tester.

2 - Fabric.

3 - Scissors.

4 - scale

Stomach bursting test.

Ball bursting test.

1. Stomach Strategy:

An is clasped over an expandable stomach. The stomach is extended by liquid strain to the mark of example burst. The distinction between the absolute tension expected to break the example and the strain expected to swell the stomach is accounted for as the bursting strength.

Fabric bursting test by stomach technique

Fig: Fabric bursting test by stomach technique

Contraption and Materials:

Pressure-driven Stomach Bursting Tester: A testing machine that meets the prerequisites of. In instances of debate, an engine-driven tester will be utilized except if the buyer and the provider concur in any case.

Pressure driven Stomach Bursting Tester

Fig: Pressure-driven stomach bursting tester

Clips: For solidly and consistently getting the test example between two annular, plane, equal, and ideally tempered steel surfaces, without slippage during the test. Utilize adequate strain to impact the practicable minimization of slippage.

Stomach: A 48 mm (1.875 in) stomach of Shaped engineered elastic, 1.80 6 0.05 mm (0.070 6 0.002 in.) in thickness with built-up focus, braced between the lower cinching plate and the remainder of the device so before the stomach is extended by strain under it the focal point of its upper surface is beneath the plane of the clipping surface. The strain expected to raise the free surface of the stomach plane will be 30 6 5 kPa (4.3 6 0.8 psi).

Pressure Gage: A greatest perusing pressure check of the Bourdon kind of proper limit graduated in pounds and exact all through the whole scope of its scale to inside worth of 1 % of its most extreme limit. The limit of the gauge will be to such an extent that the singular readings will be at least 25 % nor more than 75 % of the all-out limit of the measure.

Water-powered Tension Framework: A means of applying controlled expanding hydrostatic strain to the underside of the stomach until the example blasts through a liquid dislodged at the pace of 95 6 5 ml/min. The liquid is dislodged by a cylinder in the tension office of the device.

Inspecting:

Part Test: As a ton test for acknowledgment testing, take indiscriminately the number of rolls of fabric coordinated in a pertinent material detail or other understanding between the buyer and the provider. Believe rolls of fabric to be the essential testing units.

Lab Test: As a lab test for acknowledgment testing, take a full-width pattern 1 m (1 yd) long from the finish of each roll of fabric in the part test, after first disposing of at least 1 m (1 yd) of fabric from the precise beyond the roll. From each roll or piece of roundabout weave fabric chosen from the parcel test, cut a band no less than 305 mm (1 ft) wide.

Test Examples: Cut ten test examples from every pattern in the lab test with every example being.

30mm Dia

113mm Dia

Molding:

Bring the examples from the overarching air to dampness harmony for testing in the standard air for material testing Estimation.

Technique:

Make all tests on examples adapted in the standard air for testing materials as coordinated.

Hand-Driven Tester:

Embed the molded example under the mount, drawing the example rigid across the plate, and clasp the example set up by bringing the cinching switch as far to one side as could be expected. Turn the hand wheel, clockwise at a uniform speed of 120 rpm until the example explodes. Quit turning the hand wheel at the moment of the burst of the example.

Following the burst and in fast progression, discharge the clipping switch over the example.

Quickly discharge the burden on the stomach by turning the wheel counterclockwise to its beginning position and record the strain expected to swell the stomach (tare pressure). Record the all-out pressure expected to crack the example.

Engine Driven Tester:

Embed the example under the stand, drawing the example rigid across the plate, and clip example set up by bringing the bracing switch as far to one side as could be expected

Swell the stomach by moving the working handle to one side.

While the stomach is blowing up, grab hold of the hook that is situated beneath, or to one side, of the working

At the moment of the crack of the example, swing the lock to the extent that it will go to carry the working handle to a standing-by (nonpartisan) position. Record the all-out pressure expected to break the example.

Following the crack, and in fast progression, discharge the bracing switch over the example.

Result: Mean bursting strength estimated in Kn/m2

2. Ball Bursting Test:

This test is finished by covering fabric.

Not really for common knitted fabrics.

In the test a 25 mm measurement steel ball is gone through the extended fabric can the power is required to do so the recorded.

This test can not be conveyed utilizing a connection on a standard tractable tester.

The outcome from this test isn't straightforwardly practically identical to the aftereffect of the stomach bursting test.

This test measures force just not the power per unit region.

Ball busting test technique

Fig: Ball bursting test technique

Importance and Use: This strategy for the assurance of stomach-bursting strength of knitted, nonwoven, and woven fabrics is being involved by the material business for the assessment of a wide

Estimation:

Ascertain the bursting tension of every example by taking away the tare pressure expected to swell the stomach from the absolute strain expected to crack the example. Report the strain perusing of every individual example and the normal for every research facility inspecting unit and the parcel. Report the sort of bursting tester utilized.