Understanding Calibration

Calibration, a term widely used in science, engineering, technology, and even everyday life, refers to the process of adjusting or fine-tuning a measuring instrument or system to ensure its accuracy and reliability. Whether it's a thermometer, a medical device, or a piece of industrial machinery, calibration plays a crucial role in maintaining consistent and trustworthy measurements. This article delves into the definition of calibration, its significance, and its applications across different domains.

Defining Calibration

Calibration can be succinctly defined as the systematic process of comparing the measurements obtained from a device or instrument against a reference standard of known accuracy. The goal is to identify and correct any discrepancies between the instrument's readings and the true values provided by the reference standard. By doing so, the instrument's accuracy, precision, and reliability are optimized, ensuring that subsequent measurements are as accurate as possible.

The Significance of Calibration

Accurate measurements are the cornerstone of scientific research, industrial processes, healthcare, and various other fields. Calibration ensures that the data collected and decisions made based on these measurements are trustworthy, which is paramount for maintaining quality, safety, and efficiency. Here are some reasons why calibration is of utmost importance:

Accuracy and Reliability: Instruments tend to drift over time due to factors such as wear and tear, environmental conditions, and aging. Calibration corrects for these deviations, ensuring that the instrument consistently provides accurate and reliable results.

Quality Assurance: In industries like manufacturing and production, precise measurements are vital for ensuring the quality and consistency of products. Calibration prevents faulty products from being manufactured due to inaccurate measurements.

Compliance and Standards: Many industries are subject to regulatory standards and guidelines that mandate the use of calibrated instruments. Calibration ensures that organizations adhere to these standards, avoiding legal issues and potential financial penalties.

Research and Development: In scientific research, accurate measurements are essential for drawing valid conclusions and advancing knowledge. Calibration guarantees that experimental results are credible and can be replicated.

Safety: In fields like healthcare, aviation, and automotive engineering, inaccuracies in measurements can lead to life-threatening situations. Calibration of medical equipment, aircraft instruments, and safety systems is crucial for safeguarding human lives.

Applications of Calibration

Calibration has diverse applications across various industries and fields:

Laboratory Sciences: Instruments like spectrophotometers, balances, and pipettes used in chemistry and biology labs require regular calibration to ensure accurate analytical results.

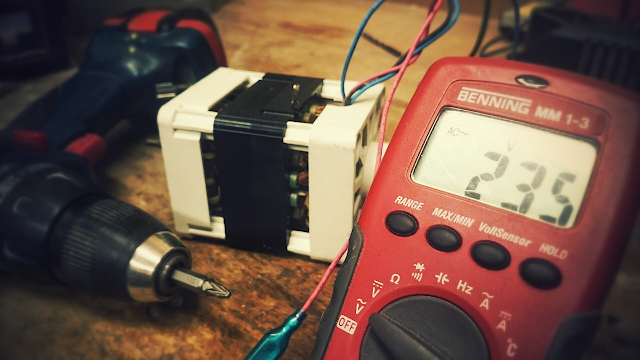

Engineering: Mechanical, electrical, and electronic equipment used in engineering, such as pressure gauges, voltage meters, and torque wrenches, must be calibrated to maintain precision in manufacturing processes.

Healthcare: Medical devices, including blood pressure monitors, thermometers, and MRI machines, undergo calibration to guarantee accurate diagnostics and treatment.

Information Technology: Computer monitors, printers, and network equipment require calibration for color accuracy, image quality, and data transmission precision.

Meteorology: Weather forecasting and climate monitoring instruments like barometers, anemometers, and rain gauges are calibrated to provide accurate weather predictions.

Calibration is an indispensable process that ensures accurate measurements and reliable data across various sectors, ranging from science and technology to healthcare and manufacturing. By comparing instruments against reference standards and making necessary adjustments, calibration enhances the precision and reliability of measurements, underpinning the quality, safety, and effectiveness of a wide array of processes and applications.